Biopharmaceutics refers to the study of medical drugs that have been

created utilizing medical biotechnology. This includes nucleic acids such as

DNA and RNA, bacterial and viral strains, and even proteins such as antibodies.

Biopharmaceutical chemical cleaning refers to the procedure involved in

creating a controlled and clean environment whereby biopharmaceutical products

are manufactured. Most biopharmaceutical chemical cleaning is conducted in a cleanroom

– a special area whereby the concentration of transmissible particles is

restricted and controlled within specified limits.

By restricting the concentration and amount of airborne particles in

the cleanroom, the chances of contamination occurring is severely lessened.

Therefore, biopharmaceutical chemical cleaning is incredibly important since

it:

●

Prevents the introduction and entry of

contaminants into the biopharmaceutical products

●

Establishes a set of quality control (QC) and

safety control within FDA’s regulations

●

Prevents the growth of microbes in the

biopharmaceutical products

Contamination can be easily introduced into the biopharmaceutical

manufacturing line via people, tools, fluids or even the environment itself.

Since biopharmaceutics dabbles in the usage of organic and biological

substances such as antibodies, DNA, nucleic acids and even proteins, it is

important to maintain the purity and original concentration of the established

product. By establishing a set of chemical cleaning protocols,

the chances of tampering or contamination can be decreased or nullified.

Biopharmaceutical chemical cleaning is also crucial in maintaining a

set of control parameters that comply with the FDA’s stringent regulations.

Without establishing a proper set of controls, the manufactured products might

not only be below sub-par level, but might also be a health hazard towards the

general public, especially if the final product is intended to be consumed.

Therefore, it is critical that correct and ethical biopharmaceutical chemical

cleaning procedures are carried out to meet the FDA’s rigid requirements, for

both the safety and overall goodwill and health of the public.

By establishing proper biopharmaceutical chemical cleaning techniques

at your workplace, you can also prevent the growth and spread of potentially

pathogenic microorganisms. Since biological elements are brought into the

equation in a biopharmaceutical firm, these very same biological building

blocks can also serve as the breeding ground of harmful microorganisms and

bacteria, if proper health and safety rules are not undertaken. However, if

proper cleaning systems and handling techniques are conducted in a sterile

environment, the chances of bacterial growth or virulent strains spreading can

be sufficiently curbed and controlled.

Thus, it is incredibly important that proper chemical cleaning is

conducted in biopharmaceutical companies and laboratories all across the globe.

This is important to curb the growth and spread of bacteria and viruses,

prevent contamination or tampering with biopharmaceutical products manufactured

off the line and to comply with the requirements put forth by the FDA itself.

There

are many online resources which offer additional details about this subject.

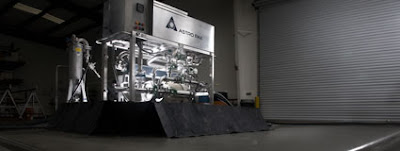

One good informational site is here. http://www.astropak.com/services.php