The ever-accelerating

pace of the aerospace and defense industry can be attributed to the

accelerating space race between the USA and USSR to serve the industry better.

The span of decades has witnessed a paradigm shift in the business leverages

made by these countries. This can be evidenced by rapid advancements in

technology and advanced experiments conducted since then. Be it the aspect of

pre-planning the activities related to the commissioning of the space launch

vehicles, or rather be it the world class maintenance and planned shut downs, a

paradigm shift has been witnessed in the field operations.

Assuring the twin

benefits of efficiency and effectiveness is one of the key strengths of the

world class passivation specialists. They assure in delivering the

environmental friendly product. “Go Green way “ has become the present day

lingo for the passivation specialists.

Basically, passivation

of military parts has its own share of blues. Most of the companies adhere to

the quality standards of the various military services and ensure that a world

class service is being delivered to the clients. It needs mentioning that the

surface enrichment plays a pivotal role in this regard. Most of the companies

offer a wide range of services in this regard.

There are several ways

of passivation of military parts. Of which, one needs to mention the post

fabrication process. This is used to remove shop dirt and free iron, along with

other metal particles from various stainless steel surfaces. The military parts

are cleaned thoroughly first and once they are cleaned, are subject to acid

bath treatments. This process will ensure a stunning shine for the parts which

look like new. Quite often most of the times, companies use alkaline solutions

to remove metallic deposits.

A world class

passivation of military parts can be assured using the passivation specialists.

Out of these, one needs to mention the passivation with the citric acid. It is

considered as one of the most versatile and safe method. This requires lesser

maintenance and is quite simpler to perform.

It needs mentioning

that while selecting an apt procedure for passivation of military parts through

the stainless steel, one needs to take account of sterility and environmental

integrity. A great deal of walk through is required to be made, as there are

many companies which provide a plethora of passivation of stainless steel

according to the various military specifications set out, such as the

ML-STD-808 A, ML-S-5002D, ML-STD-171F. They establish requirements relating to

Air Force Support equipment, weapon parts and wood and metal surfaces.

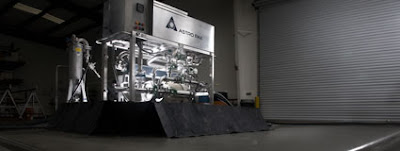

Please visit http://www.astropak.com/pickling-and-passivation-clean-room.php

for more information on this subject.

for more information on this subject.

No comments:

Post a Comment